● Cross section adaptions

Customize

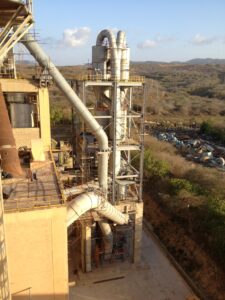

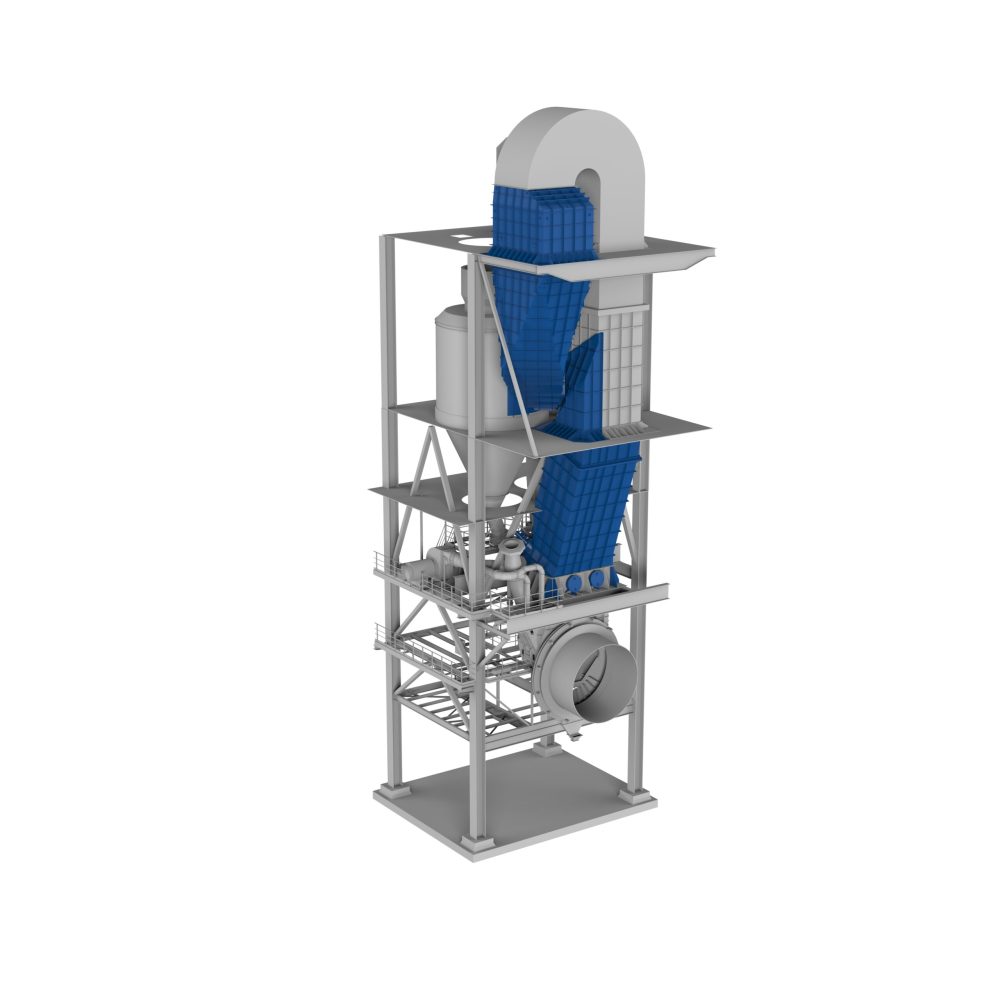

The most diverse requirements and evolved kiln systems make each kiln system a unique one. Customized small-scale modifications to correct and adjust critical cross sections and areas make their contribution to the continuous optimization of the kiln plant operation.

● Customize

Advantages

Removal of various bottlenecks

Adaptation of critical cross sections according to requirements (e.g. orifice)

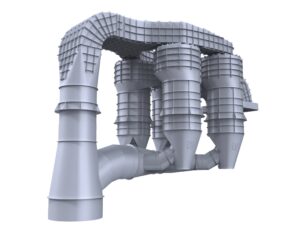

Improvement of incident flows (e.g. before fans, cyclones)

Expansions of critical cross sections (e.g. kiln inlet)

● Related services

The following products and services are used in this solution and make a significant contribution to maximizing the optimization potential.

Products

K-InTEQ

K-InTEQ

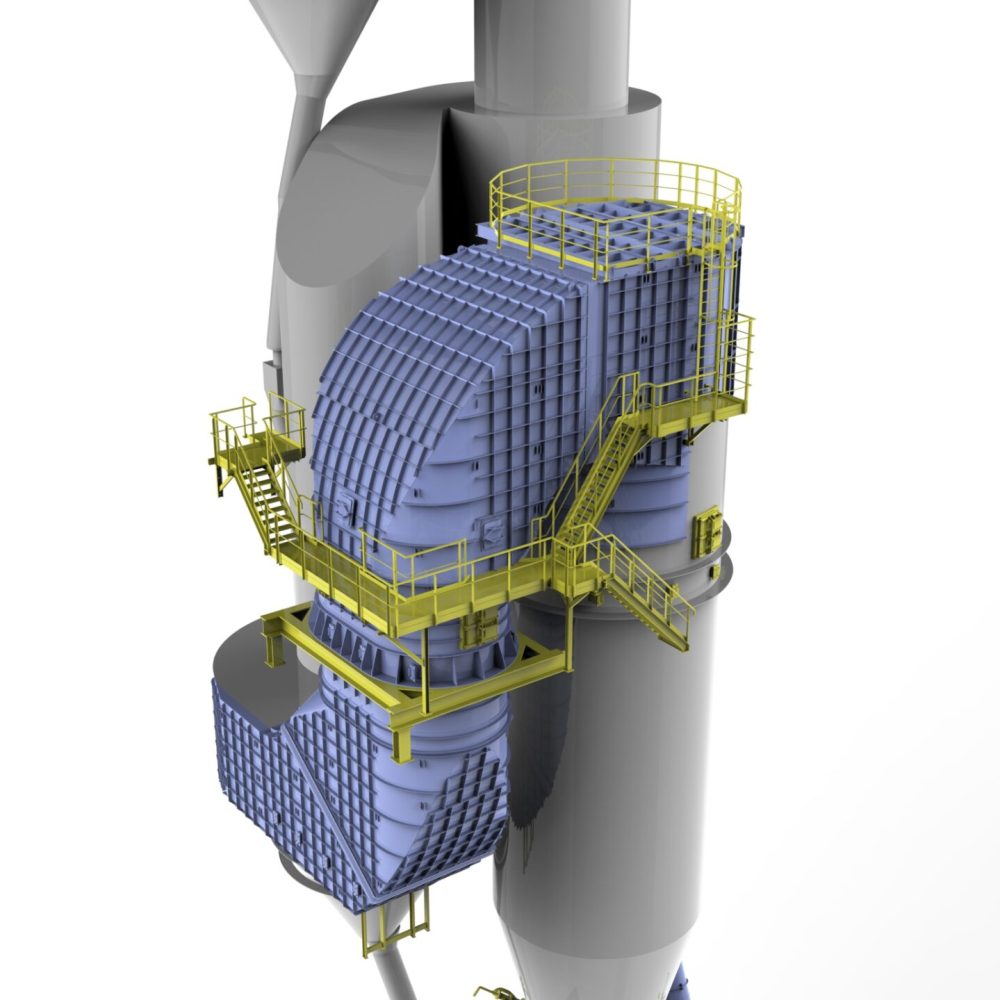

We can help you to eliminate a potential bottleneck by realizing customized modifications at the kiln inlet housing or developing an entirely new design.

Details

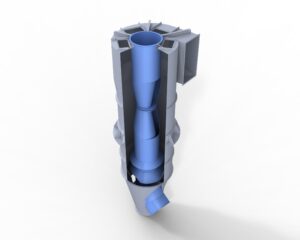

SealTEQ

SealTEQ

A reliably working kiln inlet seal is a basic requirement for stable kiln operations.

Details

OriTEQ

OriTEQ

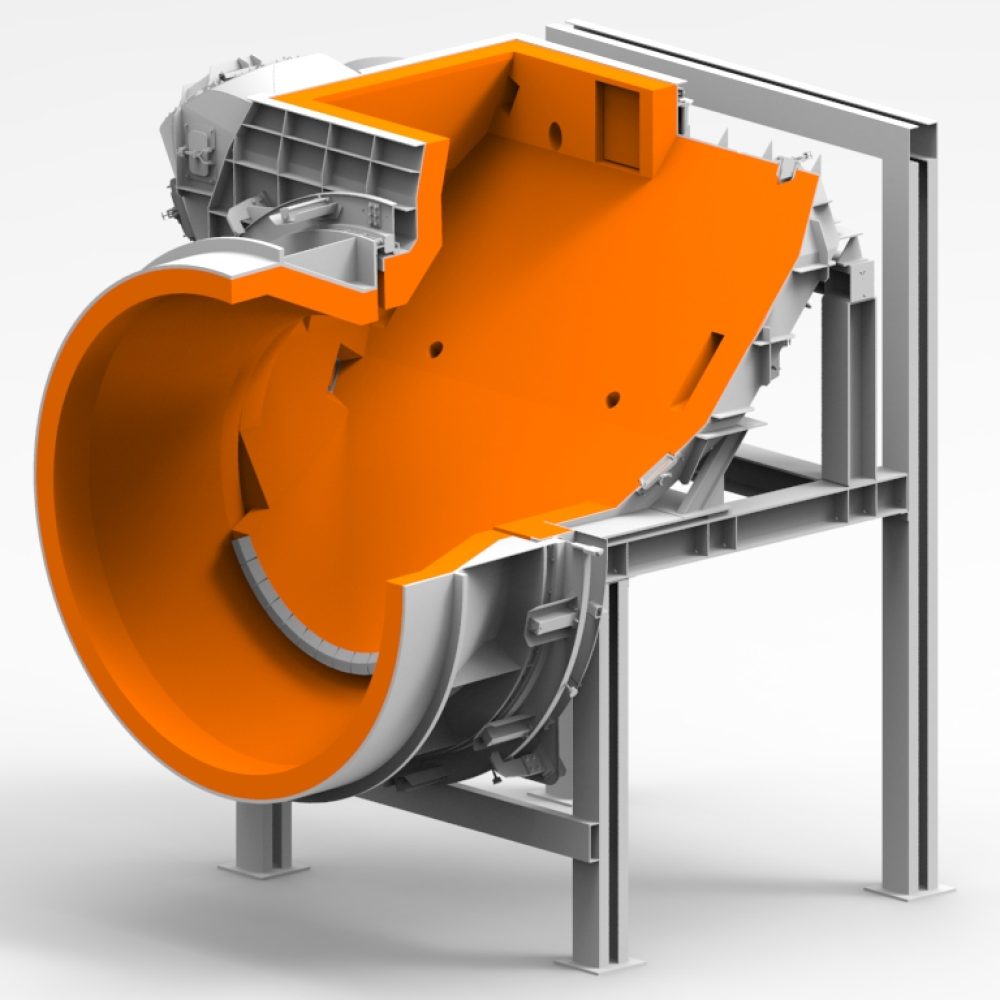

A small but essential plant area - the orifice. Small details in the design and execution have an impact and make the difference finally.

Details

Services

eSERV

eSERV

Do you see a need to increase your plant efficiency? Benefit from our expertise in pyroprocessing, drying and grinding.

Details

● Our approach

“The combination of our ideas & innovative optimization concepts with the requirements and needs of our customers creates unique solutions.”

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.