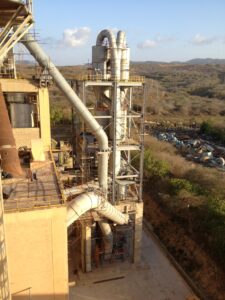

● Kiln inlets

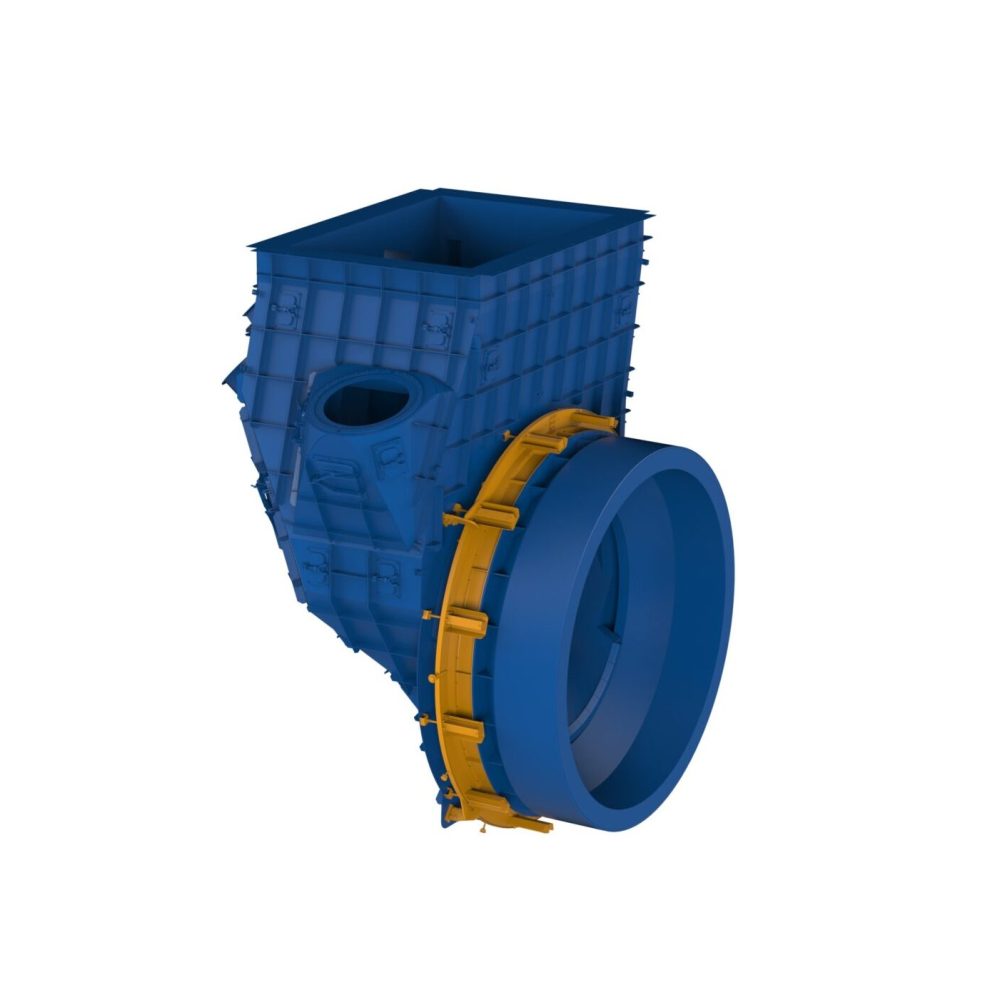

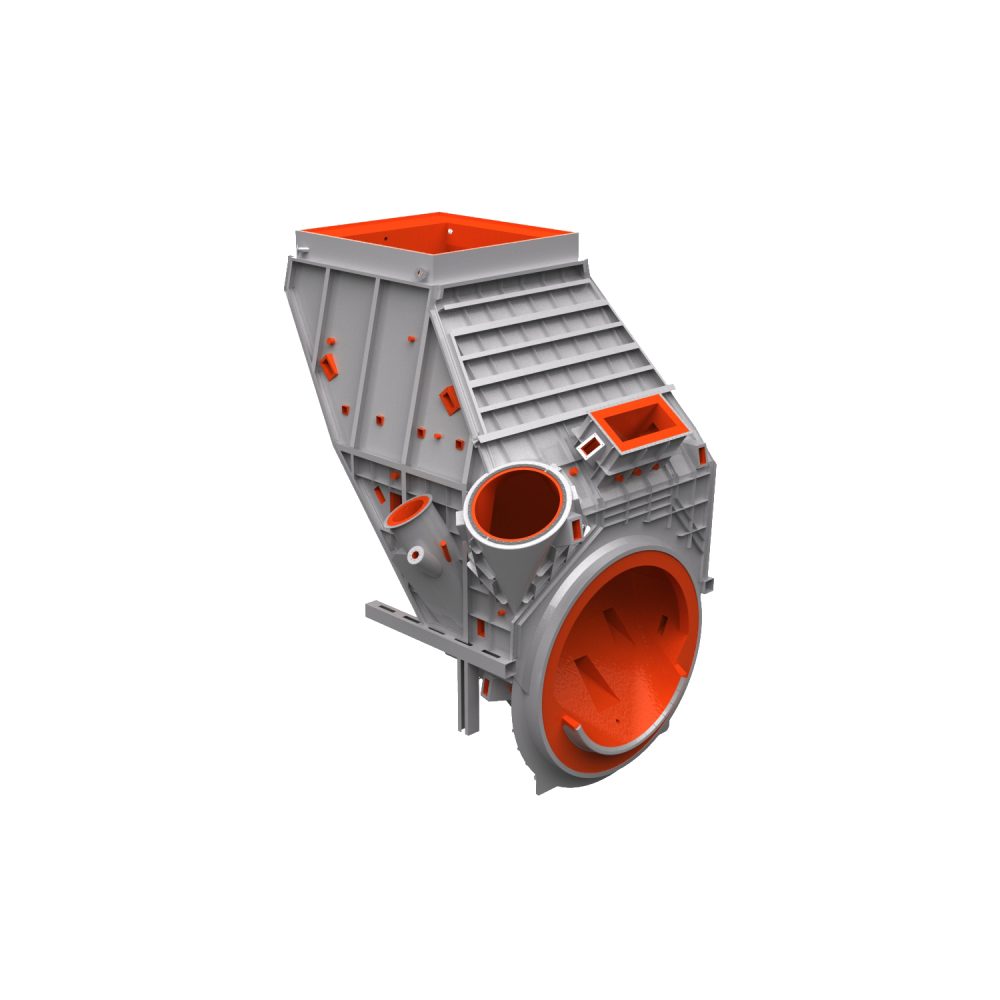

K-InTEQ

As a result of changing operating conditions at increased production as well as at raised alternative fuel rates, kiln inlets have become a “bottleneck” at many kiln lines over many years. We can help you to eliminate a potential bottleneck by realizing customized modifications at the kiln inlet housing or developing an entirely new design.

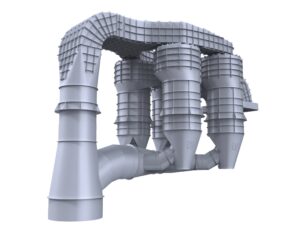

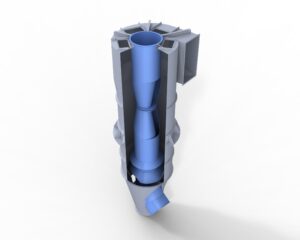

● K-InTEQ

Advantages

Enlargement of the critical cross-sections in the kiln inlet

Significant reduction of high velocities in the smallest critical cross section

Reduced dust circulation rates between the kiln inlet and the lowest cyclone stage for stable kiln operation

Improved material transport into the rotary kiln

● Related services

This product is used in the following solutions and can contribute even better to the optimization of your plant through the following offered services.

Solutions

Calciner

Calciner

Our approach to exploit the full calciner performance potential requires innovative design details – implemented in our "X5 Calciner solution".

Details

Gas bypass

Gas bypass

A customized bypass concept and solid technical engineering solutions with special design features ensure an efficient and reliable bypass operation.

Details

Customize

Customize

Customized small-scale modifications to correct and adjust critical cross sections and areas make their contribution to the continuous optimization of the kiln plant operation.

Details

Services

ePOT

ePOT

You are not sure of your optimization potential? Our process experts help you finding potentials and identifying bottlenecks.

Details

eCON

eCON

Do you appreciate help in tapping your full plant potential?

We support you in the development of customized, innovative optimization concepts.

Details

eCHECK

eCHECK

Everything tested and ready for the implementation of your plant optimization? We develop feasible solutions and take care about the integration into your plant.

Details

eSERV

eSERV

Do you see a need to increase your plant efficiency? Benefit from our expertise in pyroprocessing, drying and grinding.

Details

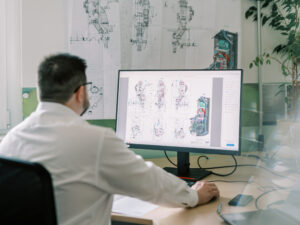

● Our approach

“Continuous improvement of unique design features as a result of many years of R&D work and experience guarantees unique products for our customers.”

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.