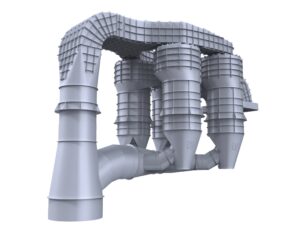

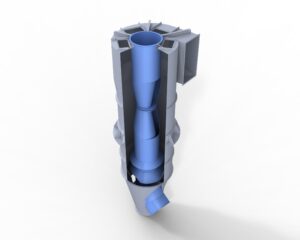

● Single dip tube cyclones

HurriTEQ-ST

State-of-the-art cyclones with attention to detail! Various challenges and our ongoing research for finding the optimal cyclone geometry were the reason for the continuous optimization of our cyclone geometries. We offer our customers tailor-made cyclone solutions for all applications.

● HurriTEQ-ST

Advantages

Customized, optimized HurriTEQ ST (Single dip tube) cyclones for various applications

Retrofit with HurriTEQ GV guide vanes at existing cyclones

Optimization of existing cyclones (improvement of separation, pressure loss, thermal efficiency)

Energy saving due to pressure loss reduction

● Related services

This product is used in the following solutions and can contribute even better to the optimization of your plant through the following offered services.

Solutions

Classifying

Classifying

Increased production output with lower specific energy consumption is often the aim of PMT projects on grinding and Classifying plants.

Details

Minerals

Minerals

Numerous plants in the gypsum, lime and other mineral industries have been customized and successfully installed.

Details

Pregrinding

Pregrinding

Effective pre-grinding is the key to increased performance in raw meal grinding.

Details

Steel

Steel

Numerous references in a wide range of industries confirm the success of PMT Premium products: including our separation solutions in the steel producing industry.

Details

Meal Bypass

Meal Bypass

Chloride is discharged by means of extracted hot meal from the lowest cyclone stage to enable a more stable kiln operation at reduced coating tendency.

Details

Flash Dryer

Flash Dryer

PMT Flash Dryers provide you with a pre-dried, fluffy fuel quality - Increase your substitution rate at the main burner.

Details

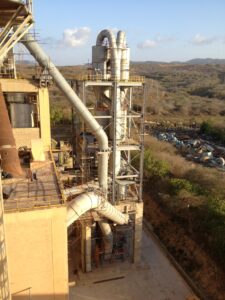

Cooler dedusting

Cooler dedusting

Single or multiple HURRITEQ DT cyclone separators connected in parallel are ideally suited for dedusting large clinker cooler exhaust air volumes.

Details

Services

ePOT

ePOT

You are not sure of your optimization potential? Our process experts help you finding potentials and identifying bottlenecks.

Details

eCON

eCON

Do you appreciate help in tapping your full plant potential?

We support you in the development of customized, innovative optimization concepts.

Details

eCHECK

eCHECK

Everything tested and ready for the implementation of your plant optimization? We develop feasible solutions and take care about the integration into your plant.

Details

eSERV

eSERV

Do you see a need to increase your plant efficiency? Benefit from our expertise in pyroprocessing, drying and grinding.

Details

eTRIAL

eTRIAL

Are you facing new separation challenges?

Test runs in our in-house technical center help you to evaluate the options.

Details

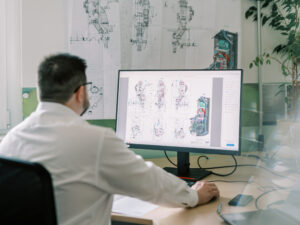

● Our approach

“Continuous improvement of unique design features as a result of many years of R&D work and experience guarantees unique products for our customers.”

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.