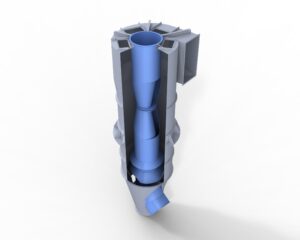

● Orifices

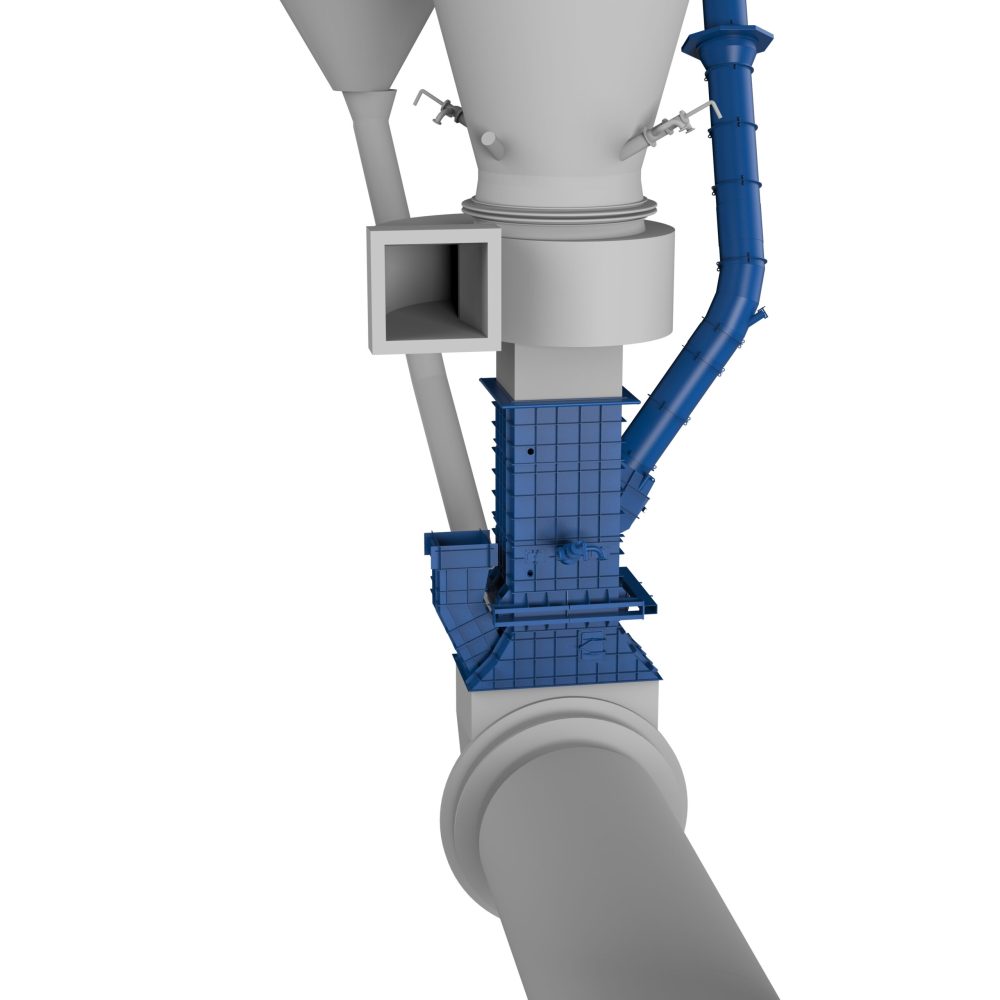

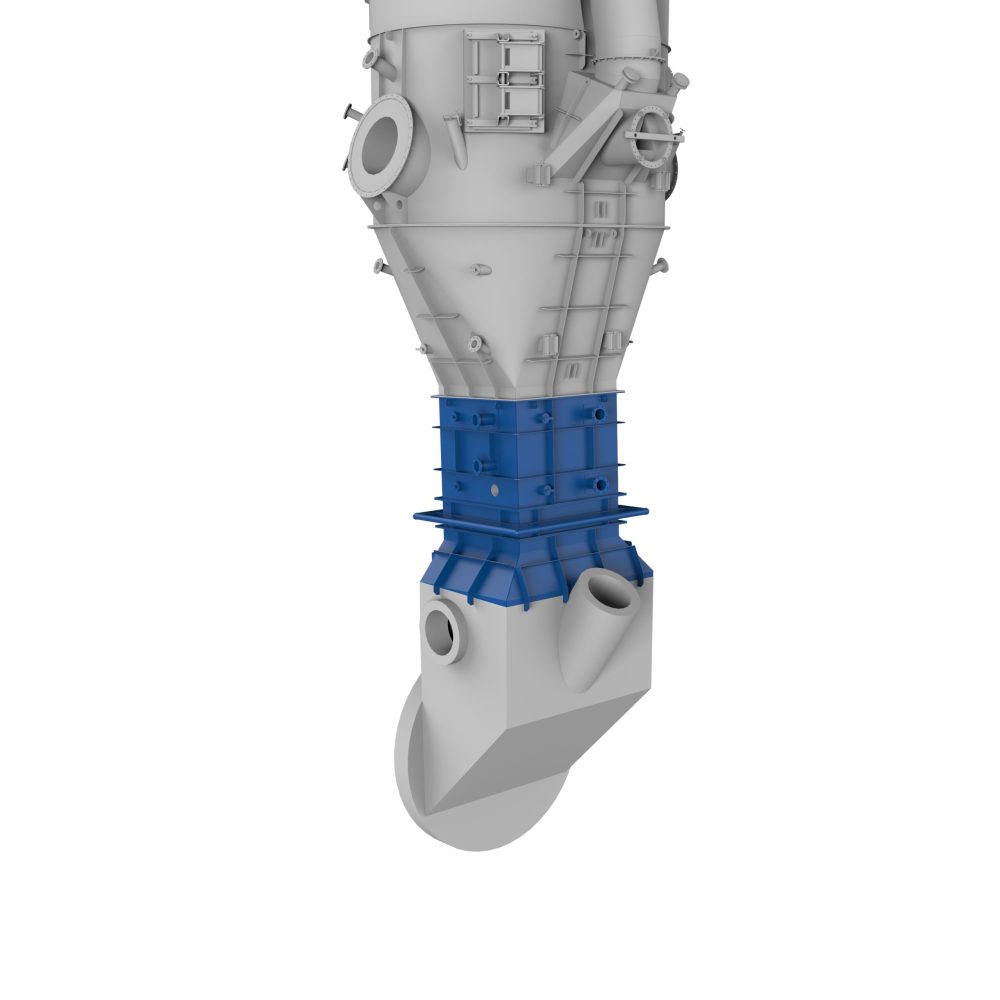

OriTEQ

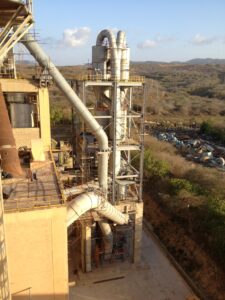

A specially designed orifice – the constriction between the kiln inlet and calciner – is one of the basic requirements to ensure efficient calciner operation, but also stable kiln operation.

● OriTEQ

Advantages

Customized orifices to prevent material breakthrough at moderate pressure loss

Special design and proven cleaning concept for the best possible reduction or prevention of build-ups

Process know-how and experience paired with referenced design criteria ensure a successful deployment of our orifices

● Related services

This product is used in the following solutions and can contribute even better to the optimization of your plant through the following offered services.

Solutions

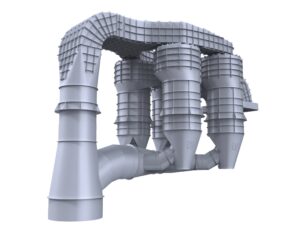

Calciner

Calciner

Our approach to exploit the full calciner performance potential requires innovative design details – implemented in our "X5 Calciner solution".

Details

Customize

Customize

Customized small-scale modifications to correct and adjust critical cross sections and areas make their contribution to the continuous optimization of the kiln plant operation.

Details

Services

eCHECK

eCHECK

Everything tested and ready for the implementation of your plant optimization? We develop feasible solutions and take care about the integration into your plant.

Details

eSERV

eSERV

Do you see a need to increase your plant efficiency? Benefit from our expertise in pyroprocessing, drying and grinding.

Details

eSIM

eSIM

Do you want to better understand your plant process? With simulations, we give you a deeper look inside your plant.

Details

● Our approach

“Continuous improvement of unique design features as a result of many years of R&D work and experience guarantees unique products for our customers.”

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.