● Expert services

eSERV

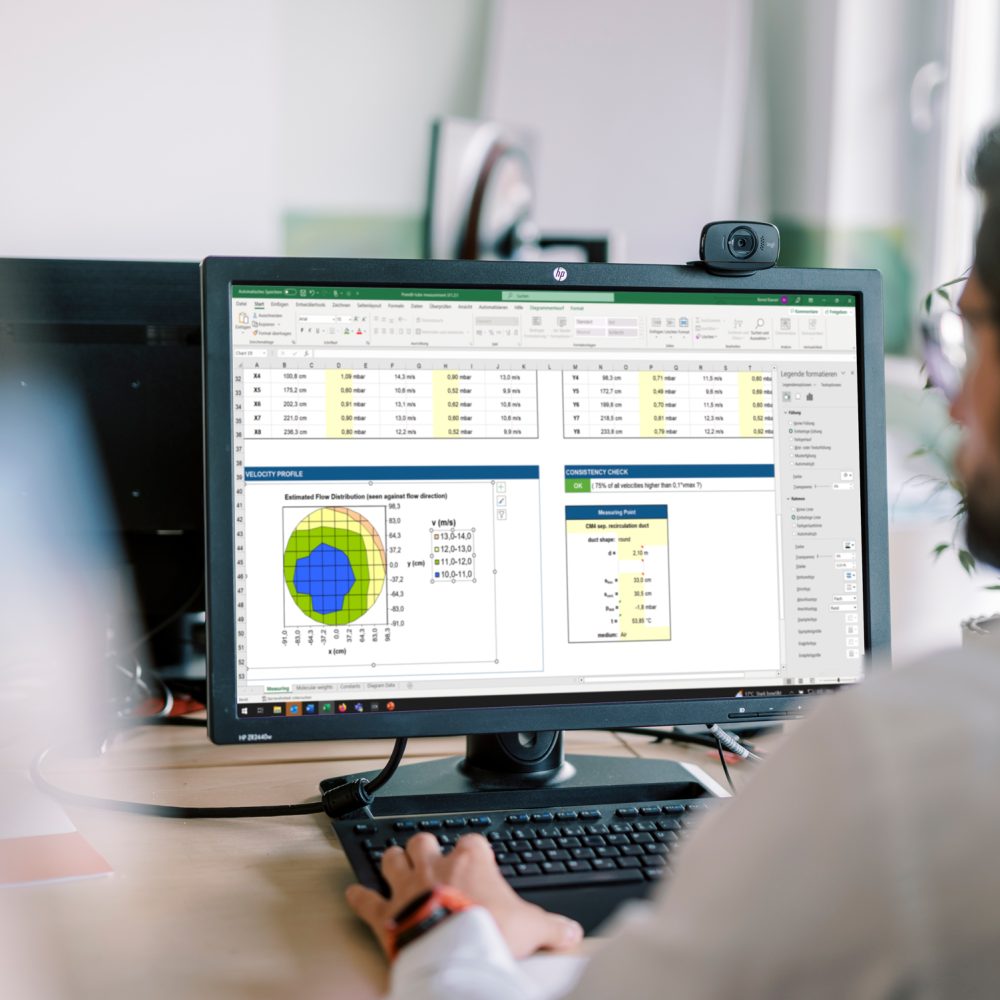

Our process engineering support is of great help in different project phases: Such as to evaluate the actual operating conditions and to point out the full optimization potential of the system. Benefit from our experience in the pyroprocessing, drying and grinding technology.

● eSERV

Advantages

Plant audits to evaluate the actual operating conditions

Identification and evaluation of performance potentials

Process engineering support for plant optimization

and other services

● Related services

This service is used for the following solutions as well as products and contributes significantly to the best possible optimization of your plants and the success of the project.

Products

ClassiTEQ-DC

X⁵-TEQ

X⁵-TEQ

The requirements for calciners are diverse - with optimizations of existing calciners and the installation of new ones, we help you to exploit the full potential.

Details

K-InTEQ

K-InTEQ

We can help you to eliminate a potential bottleneck by realizing customized modifications at the kiln inlet housing or developing an entirely new design.

Details

SplashTEQ

SplashTEQ

Optimal heat exchange through the installation of our requirement-specific, tailor-made meal splash boxes.

Details

ImpacTEQ

ImpacTEQ

The impact hammer mill is an equipment for increasing the performance of raw meal grinding.

Details

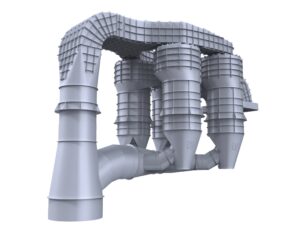

HurriTEQ-PH

HurriTEQ-PH

High separation efficiency combined with the lowest pressure drop and good thermal efficiency are the requirements for a modern cyclone stage.

Details

LoopTEQ

LoopTEQ

Efficient mixing & recirculation - with PMT's patented LoopTEQ mixing chamber at the calciner top, we help you achieving better burnout.

Details

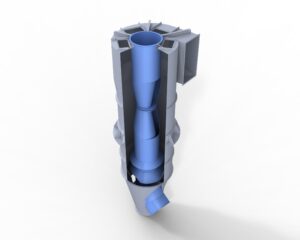

TightTEQ

TightTEQ

The smooth weight-actuated movement of the internal pendulum flap plate ensures a continuous dosing of the bulk material while preventing the backflow of the kiln gases.

Details

SealTEQ

SealTEQ

A reliably working kiln inlet seal is a basic requirement for stable kiln operations.

Details

HurriTEQ-ST

HurriTEQ-ST

State-of-the-art cyclones with special attention to detail - we offer our customers cyclones customized specifically to their application and conditions.

Details

FlashTEQ

FlashTEQ

By installing the PMT Flash dryer technology, refuse derived fuels (RDF) get beneficially pre-dried.

Details

SplitTEQ

SplitTEQ

With the SplitTEQ meal splitter, you can influence the meal distribution to several meal feeding points and thus react to the respective operating conditions.

Details

OriTEQ

OriTEQ

A small but essential plant area - the orifice. Small details in the design and execution have an impact and make the difference finally.

Details

QuenchTEQ

QuenchTEQ

Simple, efficient and a very high availability - numerous references confirm the technical quality of our quenching chamber.

Details

HurriTEQ-GV

HurriTEQ-GV

Enormous energy savings through the use of our guide vanes. As product inventors, the knowledge to make the best use of this technology is entirely in our hands.

Details

ScrewTEQ

ScrewTEQ

The air-cooled hot meal screw conveyor extractes a defined amount of hot meal and thus also chlorine from the kiln. Benefit from our experience with hot meal.

Details

Solutions

Classifying

Classifying

Increased production output with lower specific energy consumption is often the aim of PMT projects on grinding and Classifying plants.

Details

Cyclones

Cyclones

Decades of experience in the field of cyclone optimization, individual solutions and attention to technical detail form the foundation for high quality modifications.

Details

Minerals

Minerals

Numerous plants in the gypsum, lime and other mineral industries have been customized and successfully installed.

Details

Pregrinding

Pregrinding

Effective pre-grinding is the key to increased performance in raw meal grinding.

Details

Steel

Steel

Numerous references in a wide range of industries confirm the success of PMT Premium products: including our separation solutions in the steel producing industry.

Details

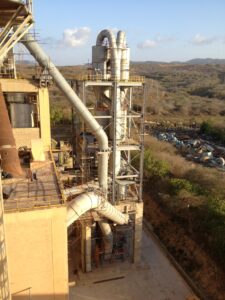

Calciner

Calciner

Our approach to exploit the full calciner performance potential requires innovative design details – implemented in our "X5 Calciner solution".

Details

Wood

Wood

Our HurriTEQ-DT double dip tube cyclone separators are ideally suited for dust removal in the wood processing industry.

Details

Multi-Meal

Multi-Meal

With the PMT Multi-point meal feed solutions, we equip your kiln line with a flexible system that allows the kiln-specific adjustment of the meal distribution as well as their feeding behaviour.

Details

Meal Bypass

Meal Bypass

Chloride is discharged by means of extracted hot meal from the lowest cyclone stage to enable a more stable kiln operation at reduced coating tendency.

Details

Customize

Customize

Customized small-scale modifications to correct and adjust critical cross sections and areas make their contribution to the continuous optimization of the kiln plant operation.

Details

Flash Dryer

Flash Dryer

PMT Flash Dryers provide you with a pre-dried, fluffy fuel quality - Increase your substitution rate at the main burner.

Details

Cooler dedusting

Cooler dedusting

Single or multiple HURRITEQ DT cyclone separators connected in parallel are ideally suited for dedusting large clinker cooler exhaust air volumes.

Details

● Our approach

“Step-by-step to success” is part of PMT’s philosophy to develop customized optimization concepts at a maximum reuse of existing equipment.

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.